Metal Stamping Dies Explained: What Goes into Building “Class A” Tooling?

The industrial metal stamping industry generally classifies custom dies and tooling into one of three tiers. For less demanding commercial metal stamping projects requiring low- to mid-volume runs, you have the option of Class B or even Class C tooling to adequately get the job done.

However, standing above Classes B and C in both quality and capability are Class A stamping dies. Class A tooling is further divided into Type 1 and Type 2 categories, all of which are discussed below.

Tool Classes Compared: Class A vs. Class B vs. Class C Stamping Dies

Class A Stamping Dies

Class A stamping dies are utilized in high-quality production applications to manufacture a wide range of commercial and industrial components. This includes precision products which require complex geometries and close tolerances, as well as custom stamped parts that require premium surface finishing, such as automotive body panels and consumer appliances.

In all cases, Class A tooling is engineered for extreme reliability and built from highly resilient materials – generally some of the toughest steels on the market. This ensures that the tool will stand up to the rigors of high-volume manufacturing and consistently produce quality stamped products within the desired specifications.

In some applications, Class A dies will churn out several million custom stamped parts over the course of the tool’s lifetime.

Class A – Type 1 Tooling

Type 1 stamping dies in the Class A category are generally larger dies used for stretching and drawing exterior panels. Typical uses include automotive body panels, large industrial panels, as well as custom stamped panels for home and appliance products.

The metal sheets that are stamped from Class A - Type 1 dies are prominently featured on the exterior of the finished product – which are often high-dollar commercial and consumer investments. That means every stamped panel must be entirely smooth and free of defects. Therefore, the solution requires a precision Type 1 stamping die which is manufactured to an even higher quality standard than the finished products.

Class A – Type 2 Tooling

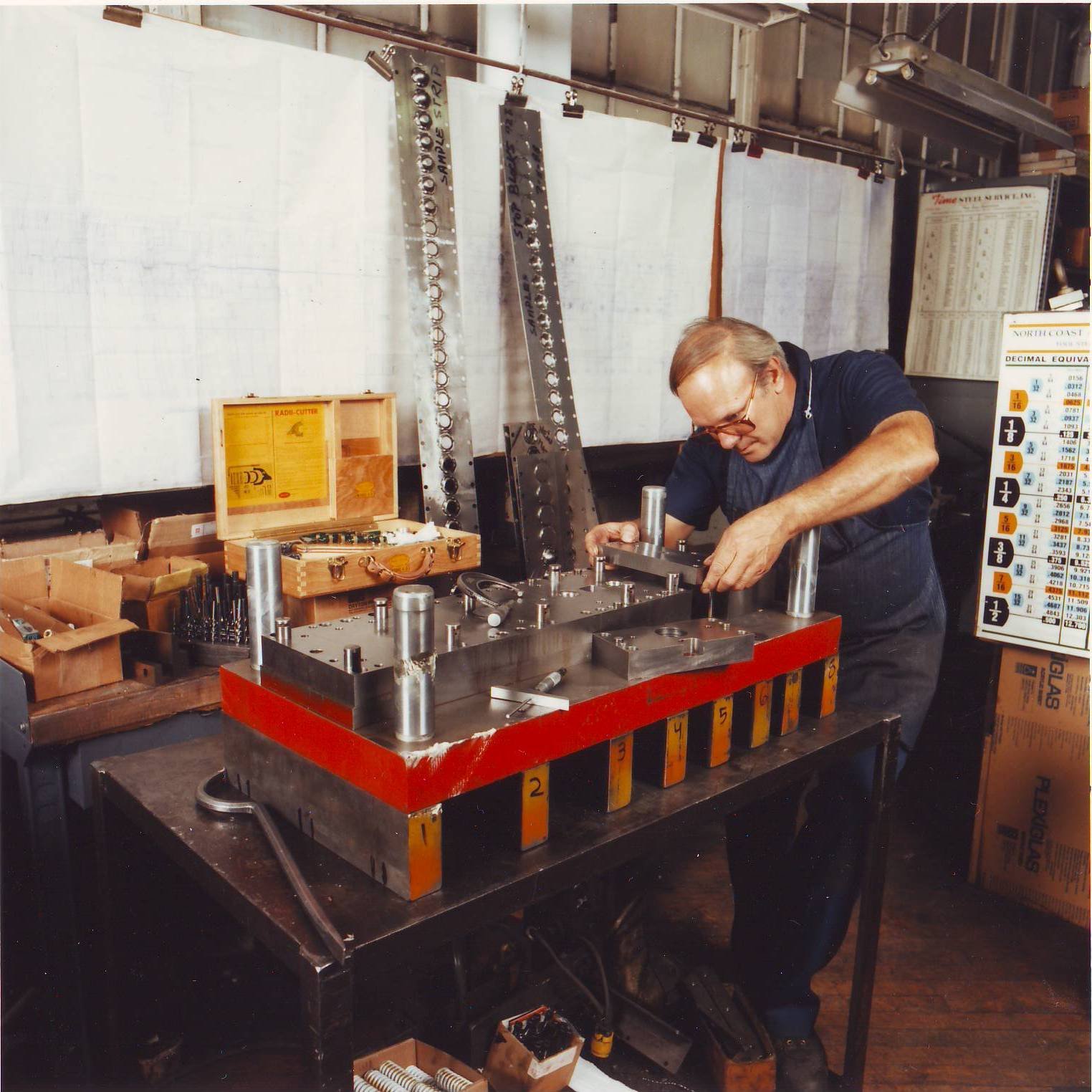

Type 2 - Class A dies demand the highest degree of toolmaking precision and consistency possible. These stamping dies and assemblies are manufactured only from the highest quality, most durable materials available – including specialized tool steels, carbide, high-performance ceramics, and aluminum die shoes.

Essentially, Type 2 dies are at the quality pyramid. If you have an extremely high-volume metal stamping project, or if your custom stamped parts require highly complex design and invariably close tolerances, a progressive Type 2 stamping die may be the key to your project’s success and sustainability.

Class B Stamping Dies

Class B tooling is the most common type used throughout the commercial and industrial metal stamping industry. While these dies are not built to the precision standards of Class A tooling, they are still built to extremely close tolerances and manufactured from highly durable tool steels.

Class B stamping dies are typically designed with a hypothetical shelf life in mind – when you have determined your expected production volume, the Class B tooling is designed and built to reliably produce stampings up to and slightly beyond that volume. However, they are not engineered to last indefinitely or perform quite as precisely as their Class A counterparts.

Class C Stamping Dies

Class C tooling is a lower-cost option that is perfectly suitable for many low- to mid-volume, less demanding metal stamping projects. Class C dies are also ideal for many custom prototyping projects for which precision dimensioning and premium finishes are not required.

Complete Custom Metal Stamping Services and In-House Toolmaking Solutions

Do your custom stamped products require a relatively simple Class B or Class C die? Or do you have a high-volume, complex metal stamping project requiring finely engineered progressive Class A tooling? In either case, quality stamped components start with proper die design and tool building.

At Master Products, our precision Class A dies are built and maintained in-house to ensure the highest degree of manufacturing accuracy and consistency possible.