A Look Inside Our State-of-the-Art Metal Stamping Facility

Quality American Metal Stamping Services – Based in Cleveland, Ohio Since 1919

Proudly based out of Cleveland, Ohio since 1919, Master Products continues to operate one of the greater Midwest’s premier metal stamping shops. Our custom stamped products and assemblies have served a diverse range of commercial sectors including IATF 16949 Certified automotive applications, industrial machinery, consumer products, as well as USS and SAE washers.

Our dedicated team of metalworking professionals combined with our streamlined production facility have enabled our family-operated business to continually deliver uncompromising quality for well over a century.

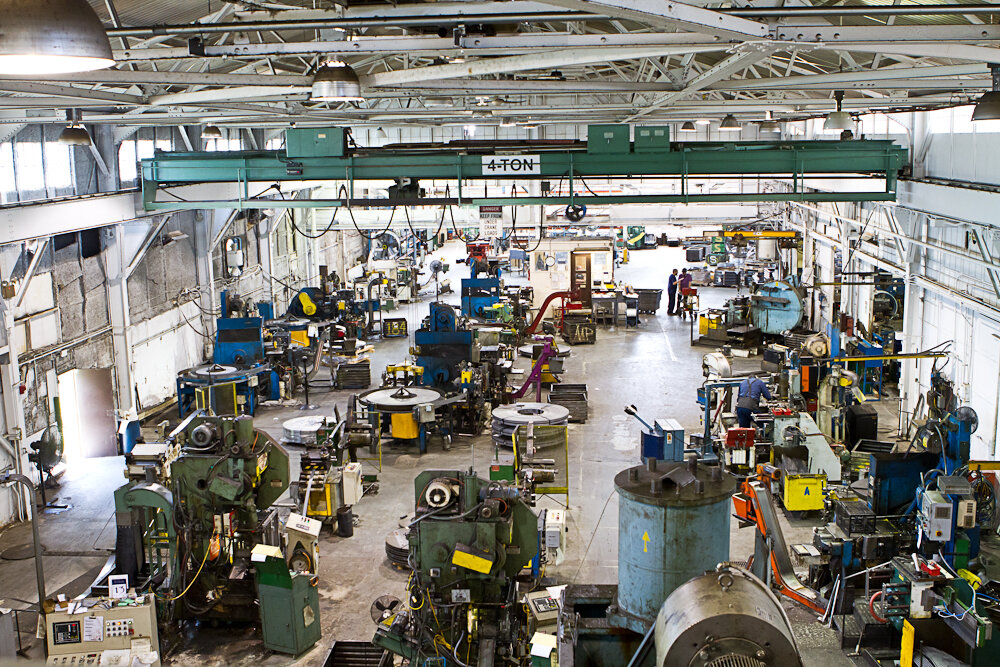

110,000 Square-Foot Metal Stamping Facility

Located at 6400 Park Avenue in Cleveland, Ohio, our state-of-the-art metal stamping facility spans more than 110,000 square feet of production space. Master Products offers superior domestic manufacturing services for leading companies throughout the greater Midwest and beyond.

52 Stamping Presses – Capacity Ranging from 15 to 250 Tons

Our facility is outfitted with some of the industry’s most capable and efficient industrial metal stamping equipment. We utilize 52 stamping presses in total delivering between 15 and 250 tons of capacity. Our stamping department has been engineered to efficiently accommodate long and short runs for both high-volume and low-volume applications.

In-House Die Making Shop – Class A Die Building Standards

Our full-service production facility includes an integrated custom die making department that operates in accordance with Class A die building standards. We offer optimized custom tooling services engineered around the unique requirements of your stamped products, enabling you to streamline your metal stamping project under one roof.

Turnkey Assembly and Secondary Operations

At Master Products, we use a custom assembly process which reduces the need for fasteners or post-production welding. This streamlines the turnkey assembly of your products, helping to further ensure cost-efficiency and on-time delivery.

We also offer a range of additional value-added services, including:

Other light assembly processes.

Drilling and tapping operations.

Custom packaging solutions.