Master Products Specializes in Proactive American Manufacturing Solutions

From Design to Delivery, From Prototype to Production, Our Metal Stamping Services Are Optimized for Unbeatable Cost, Quality and Consistency

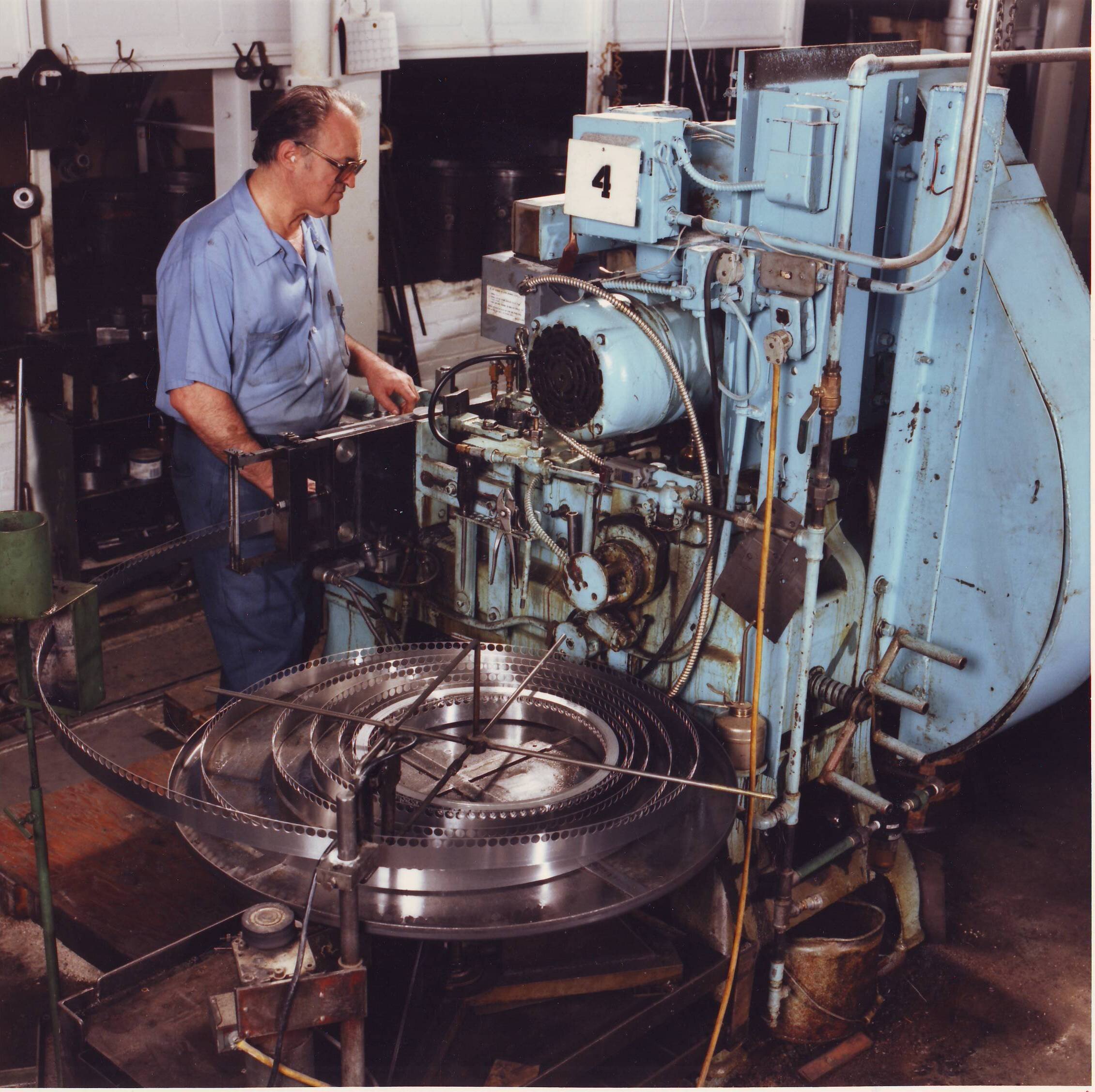

Master Products has provided a streamlined range of quality-focused American manufacturing services since 1919. Over the last century, our precision metal stamping shop has honed, refined and expanded its capabilities in conjunction with the unique needs of our commercial and industrial customers. Our prevailing goal is to deliver the most efficient, cost-effective and quality-focused manufacturing solutions possible, fine-tuned for the custom needs of your products, prototypes and assemblies.

Master Products’ state-of-the-art manufacturing facility is outfitted with a versatile range of precision metal stamping equipment.

Proactive Manufacturing Means Maximum Production Quality, Consistency and Efficiency

Being at the forefront of the manufacturing world for over a century, Master Products has evolved and progressed right alongside the industry. American metalworkers and custom metal stamping houses have always faced the challenge of meeting ever-increasing industry expectations of quality and ROI, while also offering the rapid response and quick product turnaround times that many markets demand.

The manufacturing industry’s tendency toward globalization over the last century has further exacerbated these challenges. It requires providers to diversify their metalworking services to provide larger ranges of production solutions with increased options for material selection for cost and quality optimization.

Additionally, quality providers have to manage increasingly complex global supply and inventory control networks, while exceeding customer expectations of quality and efficiency every step of the way. That’s why Master Products has spent over a century perfecting our proactive and responsive manufacturing solutions. Today, through an array of precision tooling and production solutions certified to ISO 9001:2015 quality standards, our metal stamping shop delivers everything you need from a quality metal manufacturer.

What Is Proactive Manufacturing and How Does It Benefit Your Custom Metal Stamped Products?

Master Products’ proactive manufacturing methods follow a progressive, versatile and lean model of production. From design to delivery, our manufacturing processes are optimized for your unique products, specifications and applications. That means you get the rapid-response development and quick turnaround you need to beat your competition to market, without compromising on the unbeatable quality and consistency that has been a cornerstone of Master Products since 1919.

Our engineering and design experts help you refine your products in both quality and quantity while eliminating any redundant costs along the way. When optimizing your metal stamped products for manufacturability, we factor in the capability to scale and adapt to changes in the market demand. Our streamlined production processes and inventory control solutions are driven by continuous real-time data collection, enabling Master Products to manufacture the exact parts you need exactly when you need them.

The Advantages of Master Products’ Proactive Manufacturing Services

Engineering and Design Optimization for Manufacturability

Streamlined Prototype-to-Production Solutions

Advanced Quality Control System in Accordance with ISO 9001:2015 Certification

Precision In-House Production Quality and Consistency

Manufactured in America with Precision and Pride Since 1919